Presentation of a causal model of relevant failure patterns for the development of knowledge-based AI models using the example of machine tools

Prognostics and Health Management (PHM) is a key factor for the profitable integration of production machines into digitalised production systems. Condition monitoring, remote diagnosis and the early detection of critical deviations from the process window are required for a stable digitised value creation process, in order to be able to monitor them sufficiently early and in a differentiated automated manner. Strictly data-based approaches fall far short here, as essential information about technical interactions of the causal failure states cannot be taken into account or recorded when setting up condition monitoring and failure diagnosis. However, the implementation of a model-based approach requires detailed knowledge of the physical interactions of the failure mechanisms, which is often difficult to realise for reasons of complexity and expense.

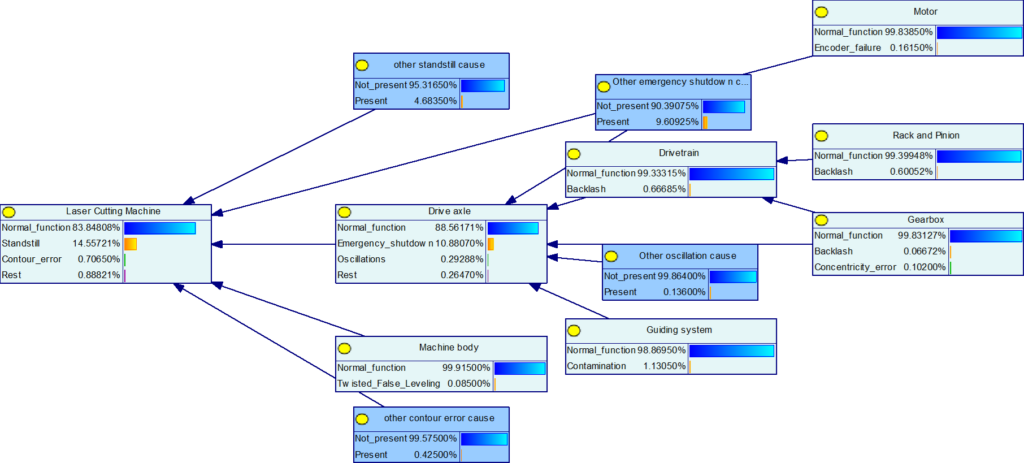

The ProKInect research project therefore takes a hybrid approach, based primarily on expert knowledge and supported by service and field data. An essential component of this is a concept for creating probabilistic models of the failure causes and effects, from which approaches to fault diagnosis can be derived and their effectiveness evaluated. In the next step, these will be used specifically to set up a new type of condition monitoring employing distributed AI agents (algorithms) which receive defined condition information from components of different manufacturers and can evaluate patterns in the overall context. Using the example of a laser cutting system, a probabilistic causal model is created, which is based on expert knowledge of real-world failure modes, the relevant causes and the causal interactions. This is relevant for condition monitoring and enables, among other things, a differential diagnosis among a set of failure causes on the basis of the recorded symptoms and additional information through evaluation by means of Bayesian networks. A section of the probabilistic FMEA is shown in Figure 1 which shows the probability of certain states of the system respectively the components. With the help of this model, critical paths that are relevant for machine availability can be identified and AI agents can be developed based on this.

Link to the whitepaper

Link to the scientific paper

Kupjetz, S.; Zenn, W.; Röding, S. (2023): Presentation of a causal model of relevant failure patterns for the development of knowledge-based AI models using the example of machine tools. In : Technische Zuverlässigkeit 2023: VDI Verlag

https://doi.org/10.51202/9783181024096 / https://doi.org/10.24406/publica-1792

Contact

- Fraunhofer Institute for Structural Durability and System Reliability LBFBartningstraße 47 64289 Darmstadt

- +49 6151 705-0

- jonathan.millitzer@lbf.fraunhofer.de